Cardboard boxes and plastic bags/liners have been used to package pavement maintenance products since the late 1970s. The plastic can impeded agitators, clog intake valves, and leave remnants on the inside of melters. And for cardboard, box cutters create a safety hazard to both the opener and the rest of the crew, while managing waste disposal necessitates extra work, additional steps, and more manpower. At Maxwell Products, we knew there had to be a better, safer way.

After years of research and development, Maxwell Products launched the industry’s first (and still the best) fully meltable packaging. We call this breakthrough PolySkinTM, our exclusive, patented, advanced packaging technology.

“[PolySkin] opened a lot of doors to us,” said Maxwell Products’ CEO, Ken Maxwell. “When we came out with PolySkin, it allowed us to focus on quality materials, because customers could see it was a premium product. We can brand PolySkin, mold it, color it. It just sets us apart.”

But who is responsible for this remarkable, industry-leading innovation? Like many projects at Maxwell Products, it was a team effort.

“I don’t know that any one person can take credit for [PolySkin],” said Marketing Director, Brent Maxwell. “My Dad [Maxwell Products founder Ted Maxwell] knew that we had to have a meltable package. He had the idea to put the product in a meltable plastic wrapper, but he knew it wouldn’t be a good product, wouldn’t deliver a stable pallet. He tried putting material in plastic buckets, but they melted slowly and added too much incompatible plastic to the material.”

The turning point in the development of PolySkin would present itself in a most unusual way. What we now know as Sir Isaac Newton’s laws of gravitation and universal motion were inspired by a simple falling apple. Maxwell Products’ development team was similarly inspired by food.

“I was in the lab contemplating meltable packaging,” Guymon said. “One of the salesmen walked into the entry of the lab, and he had his lunch in a Chinese takeout container. After a while, I finished answering his questions, and he set his lunch in the entry of the lab and forgot it, walking away. In my peripheral vision I can see this container, and I thought, I wonder. I took it, brushed out the crumbs, and walked back to the packaging bay. I measured the temperature of the sealant being packaged, had them stop the line, and filled the container with material. After leaving it overnight, I noticed the packaging wasn’t melted or damaged.”

“The next day, I went out and bought a case of chinese takeout containers. I filled them all up and spread them over the floor of the packaging bay. I’m pretty sure the guys on the packaging line thought I was nuts.”

And with that, Maxwell Products embarked on a whirlwind of development, trial and error, prototyping, and exhaustive testing. Not only did the packaging have to perform as one would expect of a meltable solution, but it also had to be compatible with Maxwell’s material, as well as provide the structural integrity needed to keep the finished pallet stable. The research and development staff tried various iterations, made necessary adjustments, and developed the next batch of prototypes.

“In the early phase, we learned a lot about how the manufacturing and filling process would affect matters, which added another layer of complexity,” Guymon said.

After painstaking research and development, Maxwell Products rolled out its game-changing PolySkin packaging along with the NUVO line of premium crack sealants. Not only has PolySkin been a hit with both public entities and private contractors, but it also began a cycle of new development within the pavement maintenance industry, as other companies raced to keep up.

“I think [PolySkin] has inspired the entire industry to put more focus on innovation,” Brent said. “I think it taught many in the industry that just because we have always done things one way, doesn’t mean we can’t do it better.”

What makes PolySkin the best meltable solution on the market?

Melts quickly and completely:

PolySkin’s quickly dissolving material eliminates the messy clogs and tangles common with the plastic liners and wrappers used in other meltable packaging. PolySkin doesn’t obstruct agitators, and its expanded bead construction keep this unique packaging afloat until fully dissolved to virtually eliminate the possibility of plugging the material intake at the bottom of the melter. And, unlike other materials, PolySkin packaged products don’t leave clumps of packaging material behind. Best of all, because PolySkin is composed of polymers compatible with Maxwell Products’ materials, it mixes thoroughly and completely into the material and doesn’t affect the product specifications.

“The real issue was that liners don’t always melt well,” Ken said. “The container melting completely was a big deal.”

Stackable, stable, and storable:

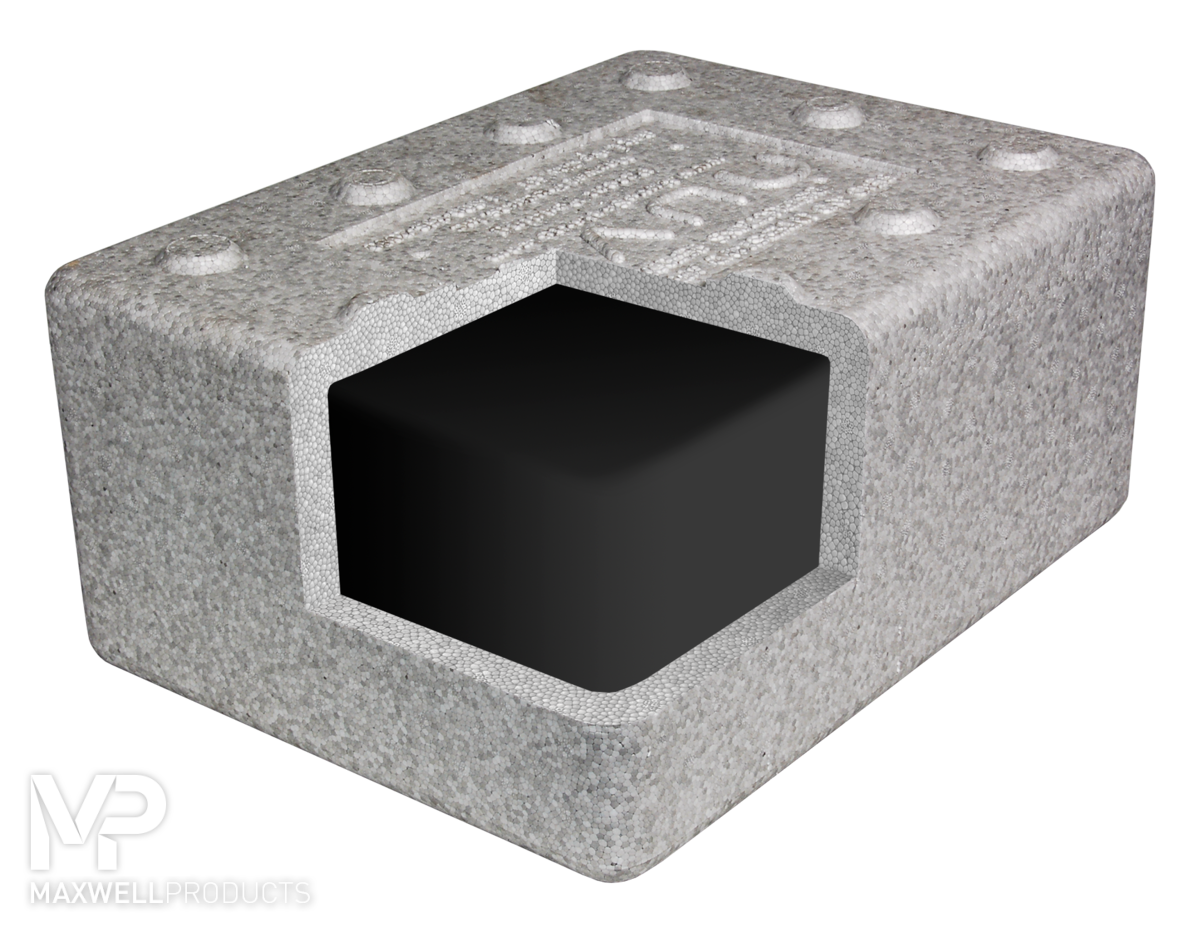

PolySkin containers do more than just transfer easily from pallet to melter, they also interlock like building blocks, which creates a structural, weather-resistant pallet. PolySkin containers don’t melt in the sun, sag, slump, or topple over when the stretch wrap is removed. In fact, PolySkin delivers the industry’s most stable pallet, allowing for worry-free, long-term, outdoor storage and trouble-free handling on the job site.

“The prototype containers had a tendency to shift some during shipping, and we knew we had to fix it,” Brent explained. “My initial concept drawings for a solutions looked a lot like building blocks, which just made it all that much cooler.”

“Our customers don’t have to worry about their pallets of material becoming a pile of mush on the ground,” Guymon added.

Faster and safer:

With no cardboard to remove or paper waste to dispose of, workers spend less time handling packaging and more time applying material. No cardboard also means no knives or razors required, which improves safety on the job site. PolySkin also saves money by requiring fewer crew.

“Time is money to our customers,” Guymon said. “If they’re spending so much time nursing their kettles, they’re not getting the work done.”

While PolySkin has been a game-changer in the pavement preservation industry, that’s not the end of the story. Maxwell’s team is continually hard at work, developing the very best materials, packaging, equipment, and more.

“At Maxwell Products, we never stop looking for new ways to innovate,” Brent said. “We are always focused on making our customers’ experience with our products better.”