View Photo

PolySkin Meltable Packaging

Think "About" the Box

Melts Quickly and Completely

PolySkin's expanded bead construction keeps packaging afloat at the top of the melter until fully dissolved to virtually eliminate the possibility of clogging the material intake at the bottom of the melter. And because PolySkin is composed of polymers compatible with our sealants, it mixes thoroughly and completely into the material.

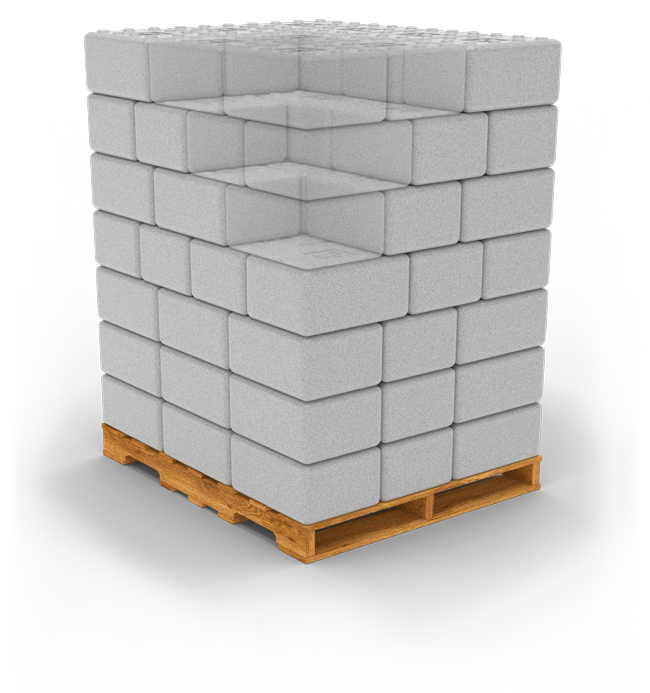

Stackable, Stable, Storable

PolySkin containers are custom molded to interlock like building blocks. This exclusive patented design provides the only structural, interlocking, weather-resistant and fully meltable container on the market. PolySkin delivers the industry's most stable pallet, allowing for worry-free, long-term, outdoor storage and trouble-free handling on the job site. PolySkin doesn't melt and sag in the sun, and pallets don't topple over when the stretch wrap is removed.

Faster and Safer

Products packaged in PolySkin go directly from the pallet into the melter. (It really is that easy.) With no packaging to remove or paper waste to dispose of, workers spend less time handling material and more time applying it. No package to remove also means no knives required. Increase your crew's safety, productivity, and efficiency with PolySkin.